The Rise of Robots in Construction and the Impact of Mission Critical Connectivity

The construction industry, long known for its reliance on manual labor, is undergoing a technological revolution. Robots are increasingly becoming an integral part of construction sites around the world, transforming the way tasks are performed. This shift not only enhances efficiency but also addresses critical challenges such as labor shortages and safety concerns. In this blog post, we’ll explore the diverse types of robots currently in use on construction sites and discuss why reliable cellular connectivity is crucial for their operation.

Construction Robotics Are the New Norm

Robots in construction are no longer a futuristic concept; they’re very much a reality. These machines take on tasks ranging from bricklaying to solar panel installation, offering a blend of precision, speed, and safety that is hard to achieve through traditional means. Let’s take a closer look at some of the key robots making waves in the industry.

Maximo (AES) – Maximo is an AI-powered robot designed for the installation of solar panels. It uses advanced sensors and computer vision to automate panel placement, significantly reducing the time and cost involved in solar installations. Learn more about Maximo.

MYRO (MyRobot) – MYRO is an interior wall painting robot that enhances productivity by autonomously painting walls with precision and minimal waste. It significantly reduces labor costs and project timelines. Discover MYRO.

Didge AI (Nextera Robotics) – Didge specializes in site management, offering comprehensive progress tracking, safety monitoring, and visual documentation with minimal human intervention. Explore Didge AI.

Raise Robotics – This platform tackles high-precision tasks such as installing facade panels, enhancing both safety and efficiency on job sites. Meet Raise Robotics.

SAM 2 (Construction Robotics) – The Semi-Automated Mason (SAM) system assists with bricklaying, increasing productivity while reducing physical strain on workers. See SAM 2 in action.

HP SitePrint – This layout robot automates the process of laying out blueprints on construction sites, improving accuracy and reducing setup time. Check out HP SitePrint.

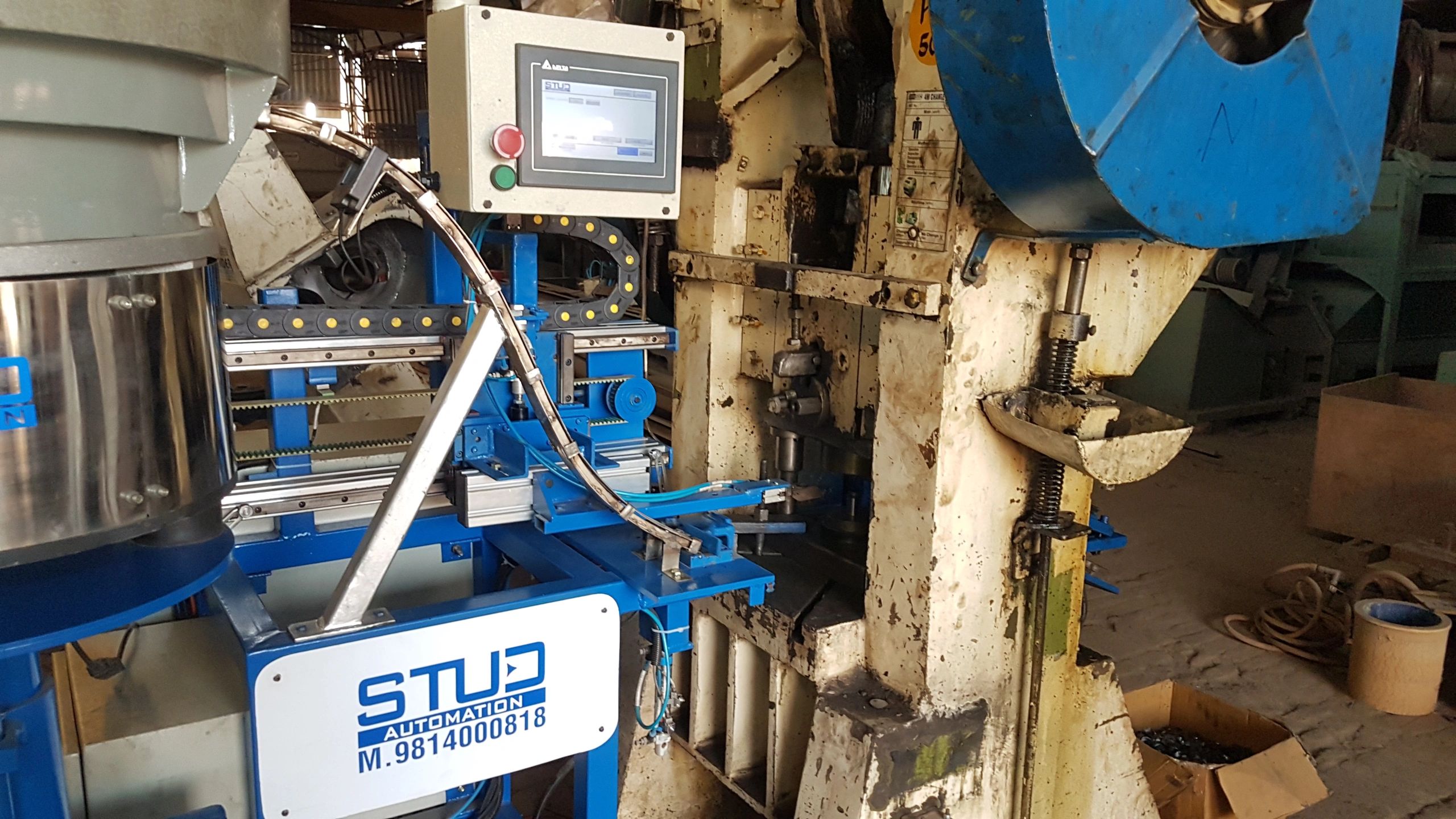

STUD Automation – This system automates the installation of studs and sheathing, streamlining the framing process and enhancing safety. Learn about STUD Automation.

Tyker – Tyker’s robots specialize in automated concrete floor finishing, boosting productivity and ensuring high-quality finishes. Explore Tyker.

Hadrian X (FBR) – Hadrian X uses 3D printing technology to autonomously lay bricks, speeding up construction time and reducing costs. Learn more about Hadrian X.

Jaibot (Hilti) – Jaibot is a drilling robot that autonomously handles ceiling drilling tasks, improving precision and reducing worker fatigue. See what Jaibot can do.

The Impact of Robots on Construction

The incorporation of robotics into construction projects is changing the landscape of the industry. Robots offer several key benefits:

- Increased Efficiency: Robots can perform repetitive tasks faster and with greater precision than human workers, leading to shorter project timelines and lower costs.

- Enhanced Safety: By taking on dangerous tasks, robots reduce the risk of injury to human workers, creating a safer working environment.

- Addressing Labor Shortages: With the construction industry facing a shortage of skilled labor, robots help fill the gap, ensuring projects are completed on time.

- Improved Quality: Robots deliver consistent, high-quality work, minimizing errors and rework.

The Role of Cellular Connectivity

From autonomous drilling to high-precision bricklaying, robots are revolutionizing the building process. For this new era of robotics, reliable connectivity is critical to ensure seamless operations on today’s job sites. By leveraging powerful cellular connectivity, these robots can seamlessly operate on-site, ensuring continuous performance even in the most challenging environments.

Traditionally, businesses have relied on connectivity provided by MNOs (Mobile Network Operators), and MVNOs (Mobile Virtual Network Operators). While there’s nothing wrong with these alternatives, they offer limited optionality, lock businesses into rigid contracts, and are hindered by roaming restrictions. Companies should have the freedom and control to access and connect their devices onto the networks of their choice but today they are hindered by outdated connectivity solutions. This lack of flexibility can be a significant hindrance on construction sites globally. Here are some common connectivity challenges robotics companies must overcome:

- Redundancy Issues: Single points of failure can lead to significant disruptions.

- Restricted Availability: Subpar performance due to roaming constraints.

- Multi-Contract Management: The complexity of managing multiple contracts with various network vendors.

- Network Vulnerabilities, Outages and Sunsets: Unplanned disruptions to network connectivity can severely impact operations.

- Contract Constraints: Being locked into contracts with connectivity vendors without the freedom to switch between networks when needed.

For robots to operate effectively on construction sites, reliable cellular connectivity is essential. eSIM technology, offers several advantages:

- Flexibility: eSIMs allow for remote provisioning and management, enabling seamless switching between cellular networks without physical SIM card replacements.

- Cost-Effectiveness: No more SIM swaps or managing multiple SIM SKUs. By reducing logistics and handling costs, eSIMs offer a more economical solution for connecting robots. 1 eSIM SKU, 1 contract from TEAL gives you access to connect your robots onto any network over-the-air.

- Reliability: Easily switch between networks remotely, ensuring the your robots remain operational, even in remote or challenging environments.

Learn why Mission Critical Connectivity from TEAL is already relied on by leading autonomous robots for unparalleled global connectivity as highlighted in this case study.

The integration of robots into construction marks a pivotal shift towards more efficient, safe, and cost-effective building practices. Cellular connectivity, powered by eSIM technology, is a critical enabler of this transformation, ensuring that robots can operate seamlessly on job sites. As the construction industry continues to evolve, the role of robotics will only grow, offering exciting possibilities for the future of building.

For construction companies looking to stay competitive, now is the time to explore the potential of eSIM technology from TEAL to streamline your operations and to ensure uninterrupted connectivity for your robots. Schedule a meeting with a TEAL expert today to find out how we can help your business.

LEARN MORE

Recent Posts

The Connectivity Gap That’s Leaving Your Surveillance Network Exposed

Teal Communications Staff2026-02-18T17:07:13+00:00

From Start Gate to Finish Line: Make Your Mission-Critical Systems 7x Faster

Teal Communications Staff2026-02-19T16:55:50+00:00

Why Reliable Connectivity Is Critical for Modern Point of Sale Systems

Teal Communications Staff2026-02-12T20:02:49+00:00