How IoT is Revolutionizing the Manufacturing Process

Over time, manufacturers across various industries have faced technological challenges when attempting to improve yields on production, generate higher margins, and operate more efficiently. However, recent advancements in IoT and network technologies have provided manufacturers with a wide set of tools to achieve these goals.

The idea of “smart” manufacturing stems from the idea of harnessing the power of data and using real-time analytics to operate machines and manufacturing facilities more efficiently. Without the Internet of Things and its associated technologies, none of this would be possible.

The emergence of the IoT space has enabled machines to remotely communicate and collect data in real-time. Companies now have the ability to strategically embed “things” such as IoT sensors on their machines, collecting relevant data and analytics and empowering them with more in-depth information about their machines than was previously possible. This allows manufacturers to make higher quality decisions, as they are equipped with accurate and powerful real-time insights and performance data. Having the ability to utilize this data is important for increasing efficiencies but is equally important in minimizing defects and identifying where improvements are needed in the manufacturing process, thus reducing the risk of costly downtime.

Since manufacturers now have the power to manage facilities and machines remotely through IoT technologies, the opportunity for automation and optimization has increased dramatically. However, security remains a major factor as there have been a growing number of attacks on manufacturers globally. Due to these attacks, network and device security has become a much larger topic of conversation recently, which is why it’s crucial to consider which networking technologies are being harnessed.

WiFi

LoRaWAN

Private LTE

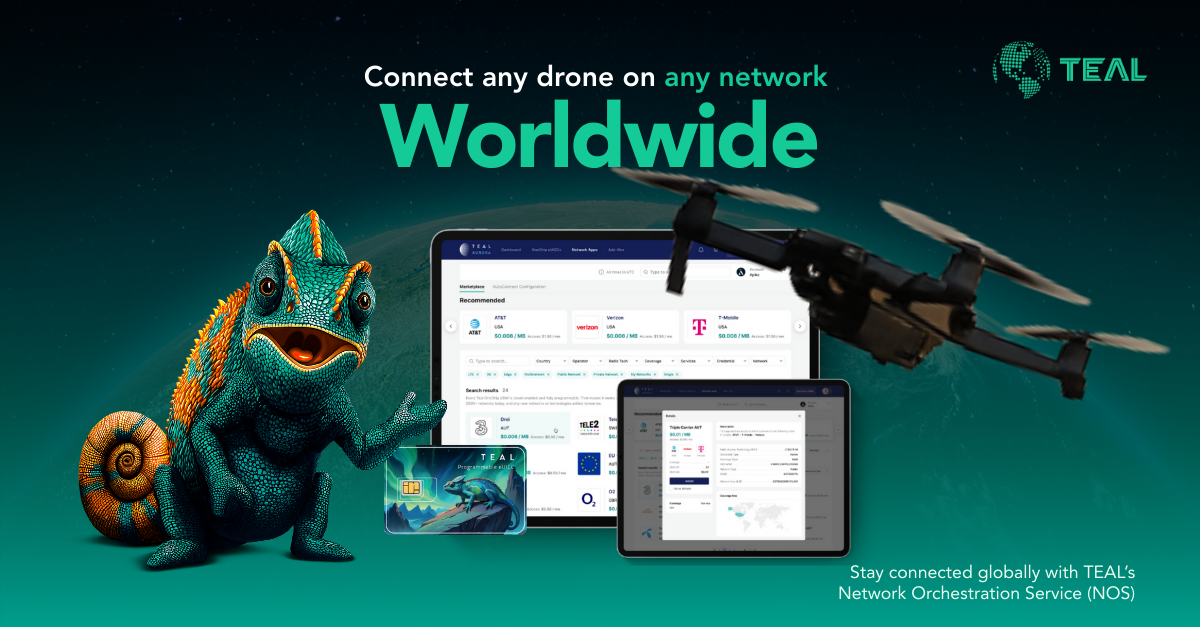

The bottom line is that every IoT use case is different and may require a combination of networking technologies in order to achieve a manufacturer’s connectivity goals. These technologies can complement each other to provide a complete, end-to-end solution, further advancing the manufacturing process in an increasingly digital world. The key for device and network operators is to partner with a credentialing platform, such as Teal Communications, that seamlessly enables IoT devices to switch between network and network technologies – ensuring that devices remain securely connected to the internet.

Recent Posts

Physical AI Is Taking Over the Real World but It Can’t Thrive Without Resilient Connectivity

Teal Communications Staff2026-01-29T23:57:08+00:00

Unleashing the Future of Drone and Autonomous Technology: An Interview with TEAL and Hextronics

Teal Communications Staff2026-01-23T21:20:16+00:00

Why Physical AI Systems Fail Without Reliable Connectivity and What CES 2026 Revealed About the Path Forward

Teal Communications Staff2026-01-15T19:52:48+00:00